our vehicle's alternator is far more than just another engine component—it's the powerhouse that keeps your entire electrical system alive and functioning. Understanding how your alternator works to charge your battery and power your vehicle's electrical systems is crucial for every driver who wants to avoid unexpected breakdowns and costly repairs.

What Makes the Alternator So Important?

The alternator serves as your vehicle's primary electrical generator, converting mechanical energy from the engine into electrical energy that powers everything from your headlights to your air conditioning. More importantly, it continuously charges your battery while the engine runs, ensuring you have the power needed for your next start-up.

At Rebuild Masters, we see firsthand how critical a properly functioning alternator is to vehicle reliability. Our USA-manufactured rebuilt alternators with new components ensure you get the dependable performance your vehicle needs without the premium price of a brand-new unit.

The Science Behind Alternator Operation

How Your Alternator Generates Power

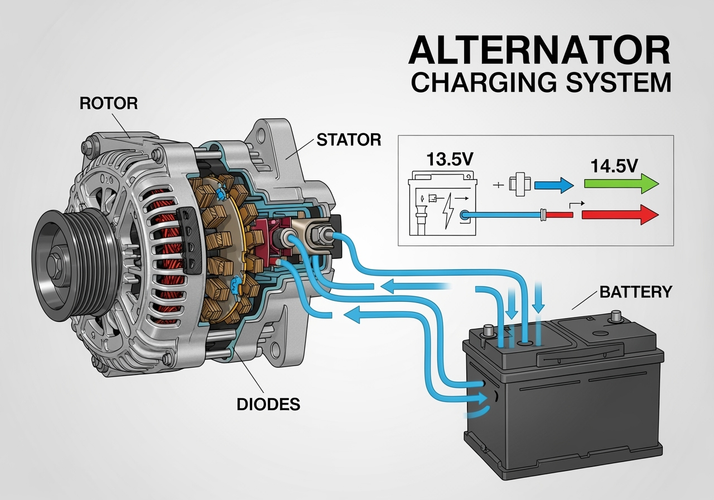

Your alternator operates on the principle of electromagnetic induction. As the engine runs, a belt-driven pulley spins the alternator's rotor, which contains powerful magnets. This rotation creates a changing magnetic field within copper wire coils (stators), generating alternating current (AC) electricity.

Since your vehicle's electrical system operates on direct current (DC), the alternator includes a rectifier assembly with diodes that convert AC to DC power. This converted electricity then flows to charge your battery and power your vehicle's electrical systems.

The Voltage Regulation Process

Modern alternators produce varying amounts of electricity depending on engine RPM and electrical demand. The voltage regulator—either built into the alternator or located separately—maintains output between 13.5 and 14.5 volts. This precise voltage range is critical:

- Too low (below 13.5V): Battery won't charge properly, leading to eventual failure

- Too high (above 14.5V): Can damage sensitive electronic components and overcharge the battery

The Battery-Alternator Partnership: A Critical Relationship

Starting the Engine: Battery Takes the Lead

When you turn your key, your battery provides the initial surge of power needed to:

- Engage the starter motor

- Fire the ignition system

- Power fuel injection systems

- Activate engine management computers

This initial power draw can require 200-400 amps for just a few seconds—far more than your alternator could provide at startup.

Running the Engine: Alternator Takes Over

Once your engine starts, the alternator immediately begins generating electricity to:

- Replenish the battery charge used during startup

- Power all electrical systems while the engine runs

- Maintain proper voltage throughout the electrical system

- Support high-demand accessories like air conditioning and heated seats

Modern Vehicle Electrical Demands

Today's vehicles place unprecedented demands on charging systems. Consider the electrical load from:

Essential Systems

- Engine management computers

- Fuel injection systems

- Ignition systems

- Lighting systems

- Safety systems (ABS, airbags, stability control)

Comfort and Convenience Features

- Climate control systems

- Infotainment systems

- Navigation and connectivity

- Power windows and seats

- Heated and cooled seats

Advanced Driver Assistance Systems (ADAS)

- Collision avoidance systems

- Lane departure warnings

- Adaptive cruise control

- Parking assistance

- Camera and sensor arrays

Modern alternators must generate 130-200+ amps to meet these demands—significantly more than the 40-60 amp units common in older vehicles.

Signs Your Alternator Isn't Properly Charging Your Battery

Early Warning Signs

- Dimming headlights or interior lights, especially at idle

- Dashboard warning lights, particularly the battery or charging system indicator

- Slow engine cranking or difficulty starting

- Electrical accessories operating sluggishly or intermittently

- Battery repeatedly losing charge despite being relatively new

Advanced Symptoms

- Complete electrical failure while driving

- Engine stalling due to loss of ignition power

- Multiple dashboard warnings appearing simultaneously

- Strange noises from the alternator area (grinding, whining, or squealing)

The Cost of Alternator Failure

Immediate Consequences

When your alternator fails, your vehicle operates solely on battery power. Depending on electrical demand and battery condition, you may have 30 minutes to 2 hours before complete electrical failure strands you.

Secondary Damage

A failing alternator can cause:

- Premature battery failure from chronic undercharging or overcharging

- Damage to electronic components from voltage fluctuations

- Starter motor stress from repeated attempts to start with a weak battery

- Engine damage in extreme cases where ignition systems fail while driving

Professional Diagnosis: Why It Matters

Proper Testing Procedures

Professional alternator testing involves:

- Load testing under various electrical demands

- Voltage output measurement at different RPM levels

- Current output verification under maximum load

- Voltage regulator function testing

- Diode and rectifier integrity checks

Avoiding Misdiagnosis

Many charging system problems can mimic alternator failure:

- Corroded battery terminals restricting current flow

- Worn drive belts preventing proper alternator operation

- Faulty wiring interrupting charging circuits

- Bad battery unable to accept or hold charge

- Blown fuses in charging system circuits

The Rebuild Masters Advantage: Quality You Can Trust

Why Choose Rebuilt Over New

Our professionally rebuilt alternators offer several advantages:

- Cost savings of 40-60% compared to new units

- Environmental responsibility through component reuse

- Proven core designs with updated components

- Comprehensive testing ensuring reliable performance

Our Rebuilding Process

- Complete disassembly and component inspection

- Replacement of all wear items: brushes, bearings, slip rings

- New electrical components: diodes, voltage regulators, wiring

- Precision reassembly with proper torque specifications

- Comprehensive testing under various load conditions

- Quality assurance verification before shipment

Maintenance Tips for Maximum Alternator Life

Regular Inspections

- Check drive belt condition and proper tension monthly

- Inspect electrical connections for corrosion or looseness

- Monitor battery condition to prevent alternator strain

- Listen for unusual noises during engine operation

Driving Habits That Help

- Avoid excessive electrical loads when engine is idling

- Allow engine to warm up before engaging high-draw accessories

- Address electrical problems promptly to prevent alternator damage

- Maintain proper engine RPM during high electrical demand periods

Professional Service Intervals

- Annual charging system testing as part of routine maintenance

- Battery testing every 6 months, especially in extreme climates

- Belt inspection and replacement according to manufacturer schedules

- Electrical system diagnosis at first sign of problems

Understanding Alternator Specifications

Amperage Output

- Passenger cars: Typically 90-130 amps

- SUVs and light trucks: Usually 130-160 amps

- Heavy-duty applications: Often 160-200+ amps

- Commercial vehicles: Can exceed 300 amps

Voltage Requirements

- Standard output: 13.5-14.5 volts DC

- High-performance systems: May include dual-voltage capabilities

- Temperature compensation: Adjusts output based on operating conditions

The Future of Vehicle Charging Systems

Emerging Technologies

- Smart alternators with variable output based on demand

- Integrated starter-generators combining starting and charging functions

- Hybrid system integration with electric motor assistance

- Advanced battery management systems for optimal charging

Environmental Considerations

Modern alternators must balance:

- Fuel efficiency through reduced parasitic drag

- Electrical demand from increasing electronic systems

- Emissions compliance through optimized engine operation

- Durability requirements for extended service life

When to Seek Professional Help

Diagnostic Expertise

Professional technicians have access to:

- Specialized testing equipment for accurate diagnosis

- Technical service bulletins addressing known issues

- Component specifications for proper replacement selection

- Warranty support for quality assurance

Quality Installation

Proper alternator installation requires:

- Correct belt routing and tension adjustment

- Secure electrical connections with proper torque specifications

- System testing to verify proper operation

- Performance verification under various load conditions

Conclusion: Your Alternator's Critical Role

Your alternator's role in charging your battery and powering your vehicle's electrical systems cannot be overstated. This hardworking component operates continuously while your engine runs, converting mechanical energy into the electrical power that keeps your vehicle's complex systems functioning reliably.

Understanding the importance of your alternator helps you recognize warning signs early, potentially saving you from roadside breakdowns and expensive secondary damage. When alternator problems arise, choosing a quality rebuilt unit from Rebuild Masters ensures you get reliable performance with USA manufacturing standards at an affordable price.

Don't wait for complete failure. If you're experiencing any signs of charging system problems, have your alternator tested by qualified professionals. Your vehicle's reliability—and your peace of mind—depend on this critical component functioning properly.